For businesses in today’s fast-paced industrial world, precision, speed, and reliability are non-negotiable. One of the most effective ways to meet these demands is by outsourcing your production needs to a professional CNC turning service, which delivers exceptional results across various industries including aerospace, automotive, and medical manufacturing.

What Is a CNC Turning Service?

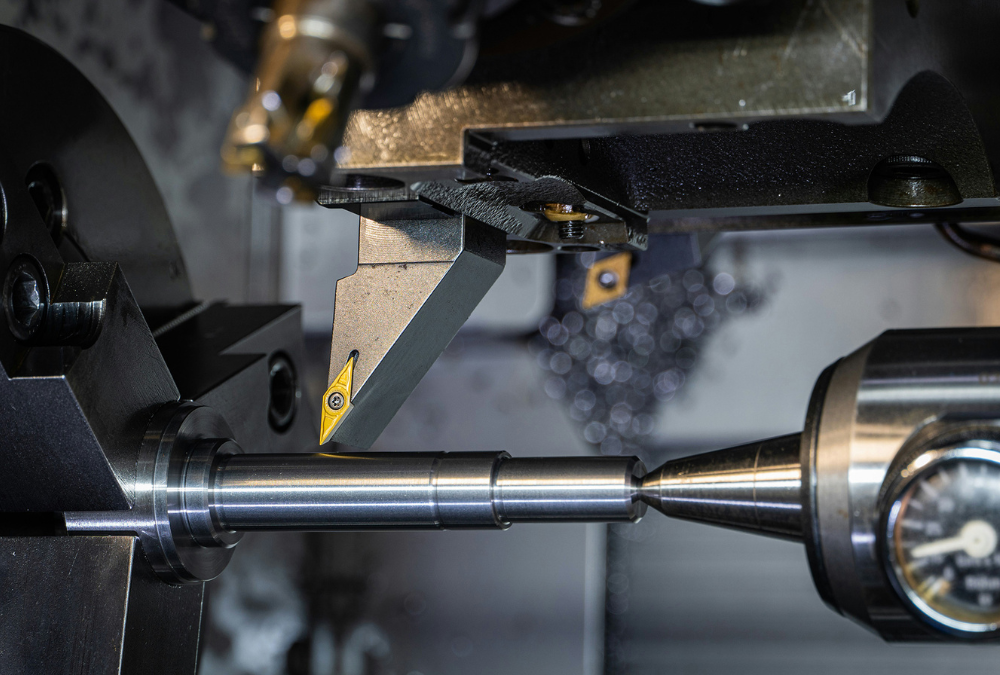

A CNC turning service utilizes Computer Numerical Control (CNC) lathes to shape metal or plastic components by rotating the material and applying cutting tools. Unlike manual turning, CNC turning is automated, incredibly precise, and consistent across large volumes. It’s primarily used for cylindrical or round parts but can also create intricate features like threads, grooves, and tapers.

How CNC Turning Works

CNC turning starts with a CAD file of the desired part. The file is translated into G-code, which the CNC machine reads to execute precise tool movements. The workpiece is mounted on a chuck and rotated at high speed while a cutting tool removes material until the final shape is achieved.

Key Components of CNC Turning

- Chuck: Holds and spins the workpiece

- Tool turret: Houses multiple cutting tools

- Spindle: Drives the rotation of the material

- Control panel: Operates the CNC software

This process ensures a tight tolerance and repeatability that’s impossible to achieve manually at high volumes.

Industries That Benefit from CNC Turning Services

Because of its precision and versatility, CNC turning is widely used across industries that require high-quality components. Here’s a quick breakdown:

| Industry | Common Applications |

| Aerospace | Engine parts, bushings, and connectors |

| Automotive | Axles, gears, pistons, and brake system parts |

| Medical | Orthopedic implants, surgical tools |

| Electronics | Housings, pins, and high-tolerance connectors |

| Industrial | Shafts, fasteners, and machine parts |

Each of these sectors relies on CNC turning for components that demand exact tolerances and functional integrity.

Types of CNC Turning Machines

CNC turning centers come in different formats and capabilities depending on production complexity and precision requirements.

1. Horizontal Turning Centers

Most common in general machining, horizontal turning centers rotate the material parallel to the floor. They’re ideal for longer, cylindrical parts and high-volume production.

2. Vertical Turning Lathes (VTLs)

These are used for larger, heavier workpieces and allow the material to be mounted vertically. This setup is great for parts like turbine casings and large bearings.

3. Swiss-Type Lathes

Used for ultra-precise small components, especially in the medical and electronics industries, these machines hold the material closer to the cutting tools for maximum accuracy.

Benefits of CNC Turning Service

Choosing a professional CNC turning service offers a range of advantages that help businesses meet product demands quickly and efficiently.

1. High Precision

CNC turning can achieve tight tolerances—down to ±0.001 inches—which is vital in aerospace, medical, and other critical applications.

2. Rapid Production

Once the CNC program is written, parts can be produced quickly with minimal manual intervention. This speeds up time-to-market and helps scale production as demand grows.

3. Cost Efficiency

Outsourcing CNC turning eliminates the need to purchase and maintain expensive machinery. It also reduces labor costs and waste from material errors.

4. Design Flexibility

CNC turning machines can produce everything from simple shafts to complex parts with threads, undercuts, and grooves.

5. Consistency Across Batches

CNC turning ensures every part—whether it’s the first or thousandth—is identical in shape and size.

Materials Commonly Used in CNC Turning

CNC turning services accommodate a wide range of materials, depending on your application’s performance, durability, and cost requirements.

| Material | Characteristics |

| Aluminum | Lightweight, corrosion-resistant, easy to machine |

| Stainless Steel | Strong, rust-resistant, suitable for harsh environments |

| Brass | Excellent machinability and electrical conductivity |

| Titanium | High strength-to-weight ratio, ideal for aerospace |

| Plastics (e.g. PEEK, Delrin) | Lightweight and cost-effective for non-metal parts |

Professionals know how to adjust machine parameters for different materials to ensure optimal results.

Common Parts Made Using CNC Turning

CNC turning services are used to produce a wide variety of functional parts, both custom and standard.

1. Shafts and Rods

Used in machinery, engines, and automotive assemblies.

2. Bushings and Sleeves

Essential for reducing friction and wear in rotating parts.

3. Fasteners and Fittings

From custom bolts to threaded connectors, turning is perfect for precision threads.

4. Housings and Enclosures

Cylindrical cases for electronics, sensors, and motor assemblies.

CNC Turning vs. CNC Milling

Though both processes are fundamental to CNC machining, they serve different purposes:

| Feature | CNC Turning | CNC Milling |

| Motion | Workpiece rotates, tool is stationary | Tool rotates, workpiece is stationary |

| Ideal For | Cylindrical parts (shafts, rods, pins) | Complex 3D shapes (brackets, plates) |

| Speed | Generally faster for round parts | Slower for intricate or multi-face parts |

| Cost | More cost-effective for high-volume runs | Better for one-off complex components |

Understanding which method fits your project can save time and production costs.

Choosing the Right CNC Turning Service Provider

A reliable CNC turning partner can be the difference between production success and failure. Here’s what to consider:

1. Experience and Expertise

Look for a provider with experience in your specific industry. This ensures they understand design tolerances, material properties, and certification requirements.

2. Advanced Equipment

Modern CNC lathes with multi-axis capabilities allow complex part production in fewer setups.

3. Quality Control

Top providers use coordinate measuring machines (CMMs), laser inspection tools, and in-process checks to ensure part accuracy.

4. Fast Turnaround Times

Ask about lead times, especially for prototyping and high-volume orders. Fast delivery without sacrificing quality is key.

5. Customization Options

From part design to final surface finishes, your provider should offer tailored solutions to meet your goals.

How the CNC Turning Process Works

Here’s a simplified breakdown of a typical CNC turning workflow:

Step 1: Design Submission

You send a 3D CAD model and part drawings with specifications like tolerances, thread types, and finishes.

Step 2: Quoting and DFM Feedback

The CNC service reviews the design and provides a quote, possibly offering Design for Manufacturability (DFM) recommendations to reduce costs and complexity.

Step 3: Programming

G-code is generated based on your model. The code controls tool paths, feed rates, and spindle speeds.

Step 4: Machining

The raw material is clamped and machined according to the G-code. Automated monitoring ensures accuracy.

Step 5: Inspection and Delivery

Finished parts are cleaned, inspected, and delivered. Optional services like anodizing or plating may be applied at this stage.

Add-On Services to Enhance CNC Turning

Many professional CNC turning providers offer additional services that add value to your parts and simplify your supply chain:

- Anodizing and Plating – Improves corrosion resistance and appearance

- Heat Treatment – Enhances material strength and hardness

- Engraving – Adds part numbers, logos, or serial codes

- Assembly – Combines multiple components into one deliverable unit

- Packaging and Logistics – Streamlines delivery and tracking

These services can reduce vendor coordination and speed up your go-to-market process.

Cost Factors in CNC Turning Services

Knowing what affects the price of a CNC turning service can help you budget better:

| Factor | Impact on Cost |

| Material Type | Harder or exotic materials are more expensive to machine |

| Part Complexity | Intricate geometries require longer machining time |

| Tolerances | Tighter specs need slower speeds and more inspections |

| Quantity | Higher volumes reduce cost per unit |

| Secondary Operations | Finishing, assembly, or inspection adds to the total cost |

Discuss these elements with your service provider to find the right balance of performance and price.

Conclusion: Why CNC Turning Service Is a Smart Investment

Choosing a professional CNC turning service is more than just outsourcing a task—it’s a strategic move to improve quality, reduce costs, and increase manufacturing efficiency. Whether you’re prototyping a new product or scaling up for mass production, CNC turning offers the precision, repeatability, and flexibility you need to stay competitive.