Heat is one of the most unforgiving forces in industrial environments. When liquid temperatures soar past the limits of conventional instruments, even the most well-maintained systems can become unreliable. For engineers and facility managers who depend on accurate flow data to keep processes running safely, that kind of failure is not an option.

This is exactly the problem that Proteus Industries set out to solve with the extreme-temperature flow meters 8000xht series. Whether you are managing a high-temperature heat-transfer loop, a demanding laser-cooling system, or any industrial process that pushes well beyond standard operating limits, the Series was designed from the ground up to remain accurate, stable, and dependable even as the heat keeps climbing.

What Is the 8000XHT Series?

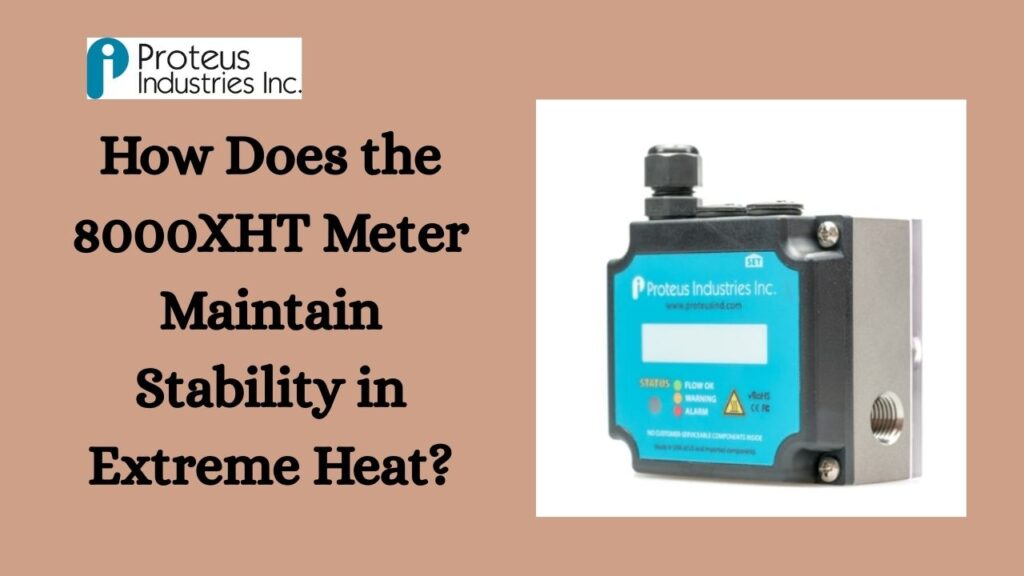

It is a line of extreme-temperature liquid flow meters manufactured by Proteus Industries. Unlike standard flow meters that begin to struggle or fail when fluid temperatures exceed typical thresholds, the 8000XHT was purpose-built to operate reliably across a far broader temperature span.

These meters serve two primary functions: measuring liquid flow rate and, in select configurations, simultaneously monitoring fluid temperature. They are compact, rugged, and engineered with the precision critical industrial applications demand. Backed by a 5-year warranty, the 8000XHT Series reflects confidence in both design and durability.

Extended Temperature Range That Goes Beyond Industry Norms

The most defining feature of the 8000XHT Series is its remarkable temperature range. Standard models support fluid temperatures from -40 °C to 200 °C (-40 °F to 392 °F), which already exceeds what most conventional flow meters can handle. For even more demanding applications, customized versions extend that envelope further — from -60 °C to 160 °C (-76 °F to 320 °F) — giving engineers greater flexibility when designing systems that experience wide thermal swings.

This wide operating window is not just a specification on paper. It reflects real engineering decisions made at every layer of the meter’s design, from materials selection to internal component tolerances. The meter does not merely survive high temperatures it continues to deliver accurate, repeatable measurements through them.

Material Engineering: Built to Take the Heat

The physical construction of the 8000XHT Series plays a central role in its thermal stability. The flow body and enclosure are built from stainless steel, a material known for maintaining structural integrity across wide temperature ranges without warping, corroding, or degrading.

Beyond heat, the design also provides magnetic, EMI, and vibration resistance, acknowledging that industrial environments rarely present a single challenge in isolation. The NEMA 4X / IP66 enclosure protects internal components from water ingress, dust, and other environmental hazards, ensuring the meter performs consistently even in wet or dirty conditions. This combination of thermal and environmental resilience is what separates a true industrial instrument from a laboratory-grade device.

Viscosity Compensation and Expert Calibration

One of the subtler but critically important ways the Series maintains measurement accuracy at high temperatures is through specialized calibration that accounts for viscosity effects. When liquid temperature changes, so does its viscosity — and that shift directly affects flow behavior. A meter calibrated only at room temperature will introduce errors as the process fluid heats up or cools down.

Proteus Industries solves this challenge with expert, application-specific calibration tailored to the exact fluid type and its expected temperature conditions. As a result, the 8000XHT Series extreme-temperature flow meter provides dependable measurements throughout the entire temperature range—not just at one calibration point. For operations where even minor measurement drift is unacceptable, this level of calibration accuracy delivers a significant advantage.

Pt1000 RTD Temperature Sensing

For engineers who need more than flow data, the models offer optional temperature measurement capability via a Pt1000 RTD sensor. This allows a single instrument to monitor both flow rate and fluid temperature simultaneously, reducing the number of sensing points in a system and simplifying wiring and integration.

The flow range supported spans from 0.95 to 60 LPM (0.25 to 16 GPM), making the 8000XHT Series versatile enough to cover a wide variety of process sizes, from small precision loops to larger industrial circuits. Multiple connection options including 9/16-18 SAE, 3/4-16 SAE, 1 1/16-12 SAE, and 1″ FNPT add to the installation flexibility.

Heat-Transfer Fluid Compatibility

Many industrial processes that operate at high temperatures depend on specialized heat-transfer fluids rather than ordinary water. It supports compatibility with a broad range of advanced thermal fluids, which represents a significant engineering accomplishment. These fluids can be chemically aggressive, viscous, or thermally demanding, and not every flow meter can handle them without seal degradation or measurement error.

By engineering the 8000XHT to work with these fluids from the outset, Proteus Industries ensures that users are not limited in their fluid selection. This compatibility, combined with the series’ temperature rating, makes it a natural choice for thermal management systems, die casting cooling loops, laser chillers, and industrial heat exchangers.

Reliable Output Signals in Demanding Conditions

Signal integrity is another area where the Series earns its reputation. The meter delivers standard 0–10 VDC, 0–5 VDC, and 4–20 mA analog outputs that integrate directly with most industrial control systems, PLCs, and data-acquisition setups. An on-board relay provides a redundant interlock capability, allowing the system to trigger alarms or shutdowns if flow falls outside the acceptable range.

This combination of analog outputs and a relay switch means the 8000XHT can function both as a monitoring device and as an active safety component within a larger process control architecture.

Real-World Applications for Extreme-Temperature Flow Meters

The 8000XHT Series finds its home across a broad set of industries where thermal management is critical. Laser-cooling systems that protect optics and beam-delivery components depend on precise, high-temperature-compatible flow measurement. Industrial die casting and injection molding operations rely on accurate coolant flow data to maintain mold temperatures and product quality. Semiconductor manufacturing, chemical processing, and power generation facilities all encounter scenarios where standard flow meters do not have the thermal range to perform reliably.

In each of these environments, the ability to measure extreme-temperature flow without sacrificing accuracy or reliability is not a luxury it is a fundamental operational requirement.

Conclusion

Series from Proteus Industries answers a genuine engineering need. By combining an industry-leading temperature range, precision viscosity-compensated calibration, robust stainless steel construction, and flexible output options, these extreme-temperature flow meters deliver the kind of stable, accurate performance that high-heat industrial processes demand.

If your application involves fluids that push past what conventional meters can handle, It is worth serious consideration. With a 5-year warranty and OEM customization options available, it is a solution built not just for today’s challenges — but for the long term.