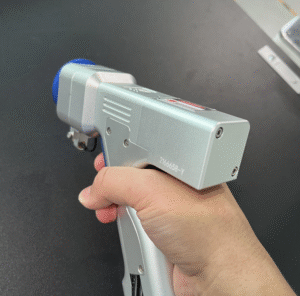

laser cutting welding machine

n modern manufacturing, speed, accuracy, and versatility are the benchmarks that determine competitiveness. Businesses across industries from automotive to heavy equipment, from aerospace to construction—are increasingly shifting toward technologies that not only streamline operations but also reduce costs and waste. Among these advancements, the laser cutting welding machine has become a pivotal tool. For enterprises seeking cutting-edge solutions, LaserChina stands out as a market leader, offering high-performance equipment designed to meet the rigorous demands of industrial production.

The Growing Demand for Integrated Laser Cutting and Welding

Manufacturers face rising global competition, which means faster turnaround times and higher-quality output are non-negotiable. Traditional processes, such as mechanical cutting followed by manual welding, often result in inefficiencies, material waste, and inconsistencies. This is where integrated laser cutting and welding machines deliver unparalleled value.

-

Accuracy and consistency: Laser technology ensures precise cuts and welds with minimal tolerance errors.

-

Operational efficiency: Combining cutting and welding in one streamlined process reduces setup times and eliminates the need for multiple machines.

-

Cost savings: Lower labor costs, reduced rework, and minimal scrap material all contribute to improved profitability.

Industries are no longer satisfied with single-function tools. Instead, they demand multifunctional, automated solutions that can perform at scale—making machines like LaserChina’s systems essential investments.

LaserChina’s Approach to Next-Generation Machines

Unlike many generic suppliers, LaserChina does not simply deliver machines; it delivers tailored solutions for industrial clients. Its laser cutting welding machines are developed with deep industry insight and engineered to align with international standards.

Key Features That Set LaserChina Apart:

-

High-Power Fiber Laser Source – Delivers clean, burr-free cuts and deep penetration welding, suitable for thick metals.

-

Dual-Function Integration – A seamless combination of precision cutting and strong weld joints in one workstation.

-

Advanced CNC Control – Automated programming ensures repeatability and reduces operator dependency.

-

Energy Efficiency – Designed to consume less power compared to conventional welding or plasma cutting systems.

-

Robust Build Quality – Built for heavy-duty industrial usage with durability that minimizes downtime.

LaserChina’s machines are not just equipment; they are productivity multipliers, enabling workshops and manufacturers to produce at scale with accuracy.

Market Trends Driving Adoption

Understanding market demand is critical to analyzing why technologies like LaserChina’s laser cutting welding machines are gaining traction. Current industrial trends highlight several factors:

-

Customization in Manufacturing: With growing requirements for unique designs and smaller batch production, laser machines offer flexibility and quick adaptation.

-

Shift Toward Automation: Businesses seek to reduce reliance on skilled labor shortages by adopting CNC-integrated systems.

-

Sustainability Goals: Precise cutting and welding reduce waste, aligning with global sustainability standards.

-

Global Competitiveness: Companies that integrate advanced machinery gain a competitive edge by improving lead times and reducing costs.

LaserChina leverages these trends, ensuring its product portfolio directly addresses the pain points of manufacturers.

Applications Across Industries

The versatility of a laser cutting welding machine makes it indispensable across multiple sectors. LaserChina’s equipment is specifically designed for B2B use, with industrial-grade performance.

-

Automotive Manufacturing: Producing precise body panels, chassis components, and welded joints with minimal error.

-

Aerospace and Defense: Meeting the strict tolerances required in aircraft and defense hardware.

-

Heavy Machinery and Construction: Fabricating durable parts for machinery, structural beams, and frames.

-

Metal Fabrication Workshops: Providing scalable solutions for businesses handling diverse project requirements.

Each application underscores the adaptability of LaserChina’s technology, offering businesses not only precision but also production reliability.

Competitive Advantages for Businesses

Investing in a laser cutting welding machine is not just a purchase—it is a strategic decision. LaserChina ensures that its customers gain long-term operational benefits:

-

Reduced Overheads: By consolidating processes, companies minimize the need for multiple setups, equipment, and skilled labor.

-

Higher Productivity: Faster cycle times directly translate to higher output.

-

Improved Quality Assurance: Automation reduces human error, leading to consistent, repeatable results.

-

Future-Readiness: With global manufacturing standards evolving, having state-of-the-art machines ensures companies remain compliant and competitive.

Why Choose LaserChina?

With decades of industry experience, LaserChina has established itself as a trusted partner for industrial clients worldwide. Its approach combines technological innovation with a deep understanding of market requirements. Key aspects include:

-

Customization: Machines can be tailored to specific material thickness, industry needs, and production volume.

-

After-Sales Support: Comprehensive technical support and training ensure smooth integration.

-

Global Standards: Compliance with CE and ISO certifications guarantees reliability.

-

Scalable Solutions: Whether for large-scale manufacturers or industrial distributors, LaserChina provides scalable options to match business growth.

The Future of Laser Cutting and Welding

The integration of cutting and welding functions represents a future where manufacturing processes are increasingly automated, precise, and environmentally conscious. As AI-driven CNC programming and IoT-enabled monitoring gain traction, businesses will demand even more efficient machines. LaserChina’s ongoing research and development ensures its products remain ahead of the curve, empowering industries to adapt and thrive in a fast-changing environment.

Conclusion

For industrial customers seeking to enhance productivity, reduce costs, and maintain uncompromised quality, the laser cutting welding machine is no longer optional—it is essential. LaserChina continues to lead this space with robust, innovative, and future-ready solutions. By aligning with global manufacturing trends and addressing real-world challenges, LaserChina enables businesses to remain competitive while preparing for the demands of tomorrow.