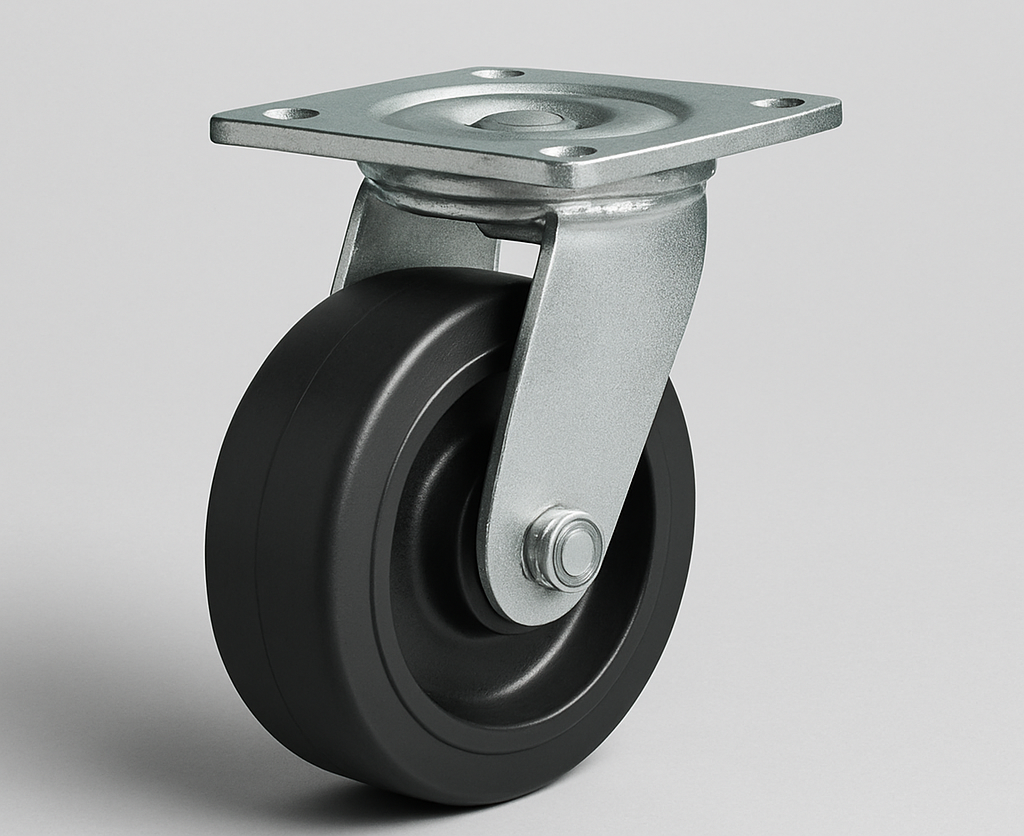

When moving heavy equipment or industrial loads, the right wheels can make all the difference. Heavy duty single wheel casters are engineered to offer superior load-bearing capacity and smooth mobility in demanding environments. Whether in manufacturing plants, warehouses, or logistics, these casters improve efficiency, reduce downtime, and protect your investments. This article dives deep into the benefits of heavy duty single wheel casters, helping you understand why they are essential for industrial applications and how to select the best options for your needs.

What Are Heavy Duty Single Wheel Casters?

Before exploring the benefits, it’s important to understand what heavy duty single wheel casters are. These are robust wheels designed with a single wheel mounted on a caster frame, capable of handling substantial loads while providing smooth maneuverability. They differ from multi-wheel casters by offering a smaller footprint, easier navigation in tight spaces, and typically better weight distribution per wheel.

Key Benefits of Heavy Duty Single Wheel Casters

1. Superior Load-Bearing Capacity

One of the primary advantages of heavy duty single wheel casters is their ability to support very heavy loads. Thanks to high-grade materials and solid construction, these casters can bear weights ranging from hundreds to thousands of pounds per wheel. This makes them ideal for industrial equipment, heavy machinery, and material handling applications.

2. Enhanced Maneuverability and Control

Unlike dual-wheel casters that can be bulky and difficult to steer, single wheel casters provide excellent maneuverability. Their design allows for easier navigation in tight spaces, sharp turns, and smoother direction changes. This is particularly beneficial in congested warehouse aisles or factory floors.

3. Durability in Harsh Environments

Heavy duty single wheel casters are often made from materials like polyurethane, rubber, or metal, offering resistance to wear, chemicals, and extreme temperatures. Industrial single wheel casters are designed to withstand tough conditions including exposure to oils, moisture, and rough surfaces, ensuring long-lasting performance.

4. Reduced Maintenance and Downtime

Due to their robust construction, these casters require less frequent replacement or repair compared to lighter-duty options. This durability minimizes maintenance costs and reduces equipment downtime, enhancing overall operational efficiency.

5. Versatility Across Applications

Whether used on carts, dollies, conveyor systems, or specialized machinery, heavy duty single wheel casters adapt to a wide range of industrial applications. Their compatibility with various mounting styles and wheel materials allows customization for specific tasks.

Types of Single Wheel Casters and Their Applications

Single Caster Wheels for Heavy Loads

Single caster wheels come in various materials such as polyurethane, nylon, or steel. Polyurethane single caster wheels provide a good balance of durability and floor protection, while steel wheels excel in extremely heavy duty or high-temperature environments.

Industrial Single Wheel Casters in Action

Industries including automotive, warehousing, and manufacturing rely on industrial single wheel casters to transport heavy parts and equipment efficiently. Their ability to handle heavy loads while maintaining smooth movement reduces worker strain and increases safety.

How to Choose the Right Heavy Duty Single Wheel Casters

Selecting the correct caster involves considering:

- Load capacity: Ensure each caster can support the expected weight plus a safety margin.

- Wheel material: Match material to floor type and environmental conditions.

- Mounting style: Depending on the equipment, choose between top plate, stem, or bolt hole mounts.

- Wheel diameter: Larger diameters roll easier over obstacles but require more clearance.

- Brake options: For safety and stability, consider casters with locking mechanisms.

Maintenance Tips for Longevity

To extend the life of your heavy duty single wheel casters, regular inspection and cleaning are essential. Remove debris that can cause wear, lubricate bearings as needed, and check for any signs of damage. Proper use within load limits prevents premature failure.

FAQ: Heavy Duty Single Wheel Casters

1. What is the difference between single caster wheels and single wheel casters?

The terms are often used interchangeably, but single caster wheels generally refer to the wheel component itself, while single wheel casters refer to the complete assembly including the wheel and mounting hardware.

2. Are industrial single wheel casters suitable for outdoor use?

Yes, many industrial single wheel casters are designed with materials resistant to weather, moisture, and chemicals, making them suitable for outdoor heavy duty applications.

3. How do heavy duty single wheel casters improve workplace safety?

By providing smooth movement of heavy equipment, reducing strain on workers, and offering reliable braking options, these casters contribute to a safer work environment.

Conclusion

Heavy duty single wheel casters offer numerous benefits including exceptional load capacity, enhanced maneuverability, durability, and versatility across industrial applications. By choosing the right casters for your equipment and maintaining them properly, you can improve operational efficiency and reduce costs.