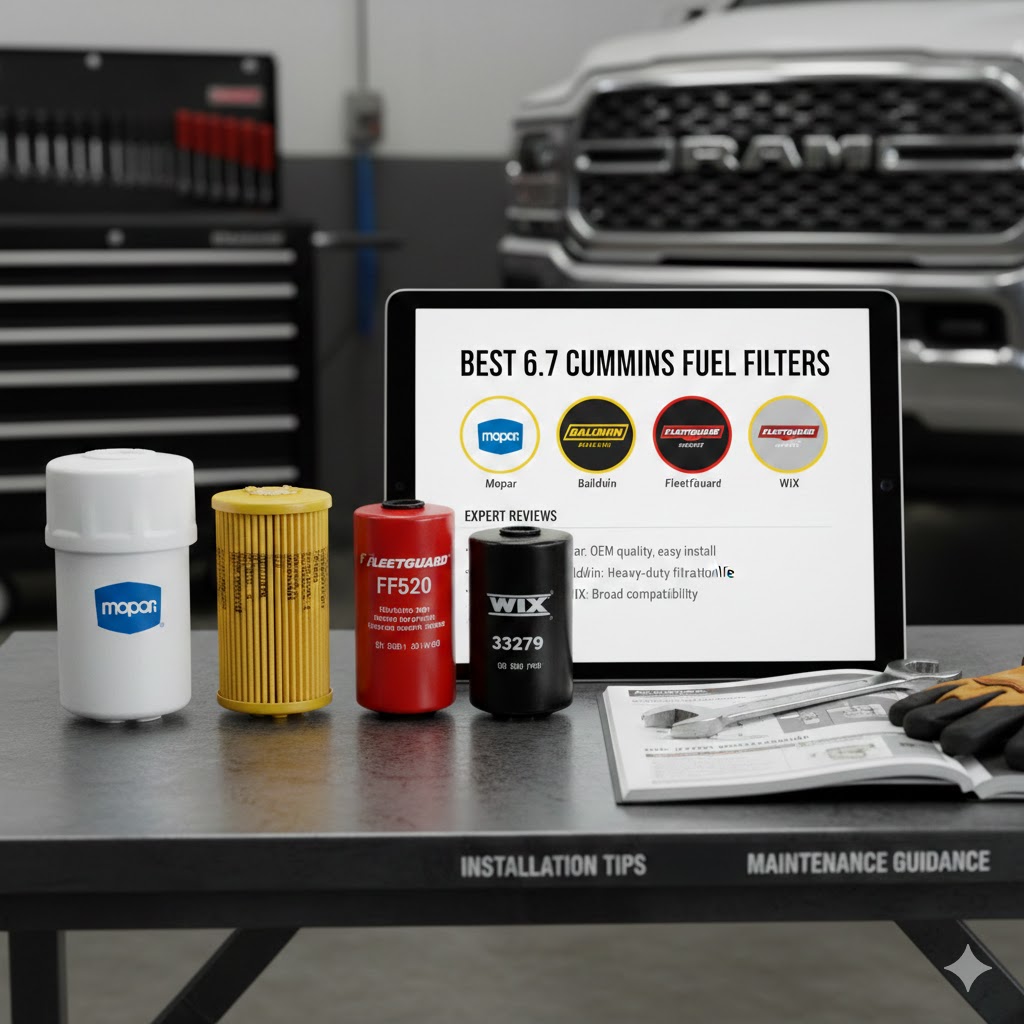

Best 6.7 cummins fuel filter

Understanding the 6.7 Cummins Fuel System

The 6.7L Cummins turbo diesel engine, found in Ram 2500 and 3500 trucks from 2007 onward, relies on a sophisticated fuel filtration system to maintain optimal performance. This engine uses a dual-stage fuel filtration system that protects the high-pressure common rail injection system from contaminants that could cause catastrophic damage.

The fuel filter setup includes both a primary fuel filter/water separator and a secondary fuel filter, working together to remove particles as small as 2-5 microns. Given that diesel fuel naturally contains water and contaminants, maintaining clean fuel filters is essential for engine longevity and performance.

Why Quality Fuel Filters Matter

Quality fuel filtration isn’t just about engine protection—it directly impacts fuel economy, power output, and emissions control. The 6.7 Cummins operates at extremely high injection pressures (up to 35,000 PSI in later models), making even microscopic contaminants potentially destructive to injectors and fuel pumps.

Poor quality filters can allow water accumulation, leading to injector corrosion and fuel system failures that cost thousands in repairs. Additionally, inadequate filtration reduces fuel atomization efficiency, resulting in incomplete combustion, reduced power, and increased exhaust emissions.

Top Fuel Filter Options for 6.7 Cummins

Mopar OEM Fuel Filter Kit

The factory Mopar fuel filter represents the benchmark standard for Best 6.7 Cummins Fuel Filter applications. This original equipment manufacturer option is engineered specifically to meet Dodge Ram’s specifications and maintains warranty compliance. The kit typically includes both primary and secondary filters along with necessary O-rings and seals.

The Mopar filter features multi-layer synthetic media that provides excellent water separation and particulate filtration. While slightly more expensive than aftermarket alternatives, it offers peace of mind through proven compatibility and consistent quality control.

Baldwin Filters BF46031-O

Baldwin has earned a strong reputation in heavy-duty diesel filtration, and their BF46031-O fuel filter delivers exceptional performance for 6.7 Cummins engines. This filter uses advanced synthetic blend media that captures contaminants while maintaining excellent flow characteristics.

Baldwin filters are known for their robust construction and superior water separation capabilities. Many fleet operators and diesel enthusiasts prefer Baldwin due to their competitive pricing relative to OEM options without sacrificing filtration efficiency.

FRAM Pro Synthetic Diesel Fuel Filter

FRAM’s professional-grade synthetic diesel fuel filter offers enhanced dirt-holding capacity compared to conventional filters. The synthetic media construction provides consistent filtration across the filter’s service life, even as it loads with contaminants.

This option appeals to owners seeking extended service intervals without compromising protection. FRAM’s design incorporates efficient water separation and includes quality gaskets that ensure leak-free installation.

WIX 33960 Heavy Duty Fuel Filter

WIX filters are widely respected in the automotive aftermarket for their engineering excellence. The 33960 model designed for 6.7 Cummins applications features high-capacity pleated media that maximizes surface area for superior contaminant capture.

WIX filters are manufactured with metal end caps and robust housings that withstand the vibration and thermal cycling common in diesel truck applications. Their filters consistently meet or exceed OEM specifications while offering excellent value.

Fleetguard FS43255

Fleetguard, a division of Cummins Filtration, manufactures filters specifically engineered for Cummins engines. The FS43255 represents OEM-level quality as Fleetguard supplies filters to Cummins for factory installations.

This filter features StrataPore media technology that provides multi-layer protection against both particulates and water. Choosing Fleetguard essentially gives you Cummins-approved filtration at potentially lower cost than Mopar branded equivalents.

Donaldson P551423

Donaldson is an industry leader in filtration technology, serving both automotive and industrial markets. Their P551423 fuel filter for 6.7 Cummins engines incorporates advanced synthetic media with exceptional dirt-holding capacity and water separation efficiency.

Donaldson filters are engineered for extreme conditions and extended service intervals, making them popular among commercial operators who demand maximum reliability. The construction quality ensures consistent performance throughout the filter’s lifespan.

Key Features to Consider

Filtration Efficiency Rating

Look for filters rated to capture particles in the 2-5 micron range, which is critical for protecting modern high-pressure fuel injection systems. Some premium filters offer even finer filtration down to 2 microns absolute, providing extra protection for injectors.

The beta rating indicates a filter’s efficiency at specific particle sizes. A higher beta ratio means better filtration performance, with beta 1000 at 4 microns representing near-absolute filtration at that size.

Water Separation Capability

Diesel fuel naturally attracts and holds water, making effective water separation essential. Quality fuel filters should remove at least 95% of emulsified water from diesel fuel before it reaches the injection system.

Look for filters with integrated water-in-fuel sensors and efficient drain systems that allow easy water removal during routine maintenance.

Dirt-Holding Capacity

A filter’s dirt-holding capacity determines how much contamination it can trap before restriction becomes problematic. Higher capacity filters extend service intervals and maintain consistent flow even as they accumulate contaminants.

This characteristic becomes especially important for trucks operating in dusty environments or using fuel from questionable sources.

Construction Quality

Premium filters feature metal end caps, reinforced housings, and high-quality gaskets that prevent bypass and ensure leak-free operation. Cheap filters may use inferior materials that fail prematurely or allow unfiltered fuel to bypass the media.

Pay attention to valve construction, particularly the anti-drain back valve that prevents fuel from draining back to the tank when the engine is off, ensuring quick starts and maintaining prime.

Installation and Maintenance Tips

Recommended Change Intervals

Dodge Ram recommends changing the 6.7 Cummins fuel filter every 15,000 miles under normal operating conditions. However, many diesel technicians and experienced owners suggest shortening this interval to 10,000 miles, especially when using biodiesel blends or operating in harsh conditions.

Trucks that frequently encounter dusty environments, extreme temperatures, or questionable fuel quality should consider even more frequent changes. The cost of premature filter replacement is minimal compared to injector or fuel pump damage.

Proper Installation Procedure

Always prime the fuel system after filter replacement to prevent air from entering the high-pressure fuel system. Fill the new filter housing with clean diesel fuel before installation to minimize dry-start conditions.

Replace all O-rings and seals provided with quality filter kits, as reusing old seals can lead to leaks and air infiltration. Apply a light coating of clean diesel fuel to O-rings before installation to ensure proper sealing.

Water Draining Schedule

Check and drain the fuel filter water separator every 5,000 miles or monthly, whichever comes first. This simple maintenance task takes only minutes but prevents water accumulation that can damage injectors and promote microbial growth in the fuel system.

During winter months in cold climates, more frequent water draining may be necessary to prevent freeze-related issues.

Common Problems and Solutions

Fuel Filter Clogging

Premature filter clogging often indicates contaminated fuel or degraded fuel quality. If filters require replacement well before the recommended interval, investigate your fuel source and consider using fuel additives that improve stability and prevent microbial growth.

Clogged filters cause reduced power, rough idling, and potential fuel starvation under load. Addressing the root cause prevents recurring issues and protects expensive fuel system components.

Air in the Fuel System

Air infiltration typically results from poor sealing during filter installation or degraded fuel lines. Symptoms include hard starting, rough running, and loss of power. Properly priming the system and ensuring all connections are tight eliminates most air-related issues.

Persistent air problems may indicate cracked fuel lines or a failing lift pump that requires professional diagnosis.

Water Contamination

Excessive water in diesel fuel can result from poor fuel quality, condensation in storage tanks, or compromised tank seals. Water causes injector corrosion, promotes bacterial growth, and reduces lubricity, leading to premature wear of fuel system components.

Using quality filters with superior water separation and maintaining regular draining schedules provides the best defense against water-related damage.

Making the Right Choice

Selecting the best fuel filter for your 6.7 Cummins depends on your specific needs, budget, and operating conditions. For most owners, sticking with OEM Mopar filters or equivalent quality brands like Fleetguard, Baldwin, or WIX ensures reliable protection without unnecessary expense. For more info

Those seeking maximum protection or extended service intervals should consider premium synthetic options from manufacturers like Donaldson or FRAM Pro. Whatever you choose, prioritize proven brands with established track records over unknown discount alternatives—your expensive fuel injection system deserves nothing less than quality filtration.